HPHT Mono Crystal Diamonds (MCD)

Our lab-grown Monocrystalline Diamond (MCD) offers exceptional quality and consistency, making it ideal for industries like medical devices, precision machining, automotive, and jewelry production. Carefully graded and inspected, these synthetic diamonds ensure optimal performance and reliability for every application, with guaranteed availability to meet your manufacturing needs.

HPHT MONO CRYSTAL

DIAMOND CHARACTERISTICS

SHAPE

SPR’s HPHT supply typically features topped octahedron shapes but can include rhombidodecahedron or plate-like crystals for larger sizes or specific orientations.

COLOR

Diamond crystals develop a slight yellow tint during growth due to nitrogen atoms trapped in the lattice, a characteristic of Type Ib synthetic crystals with around 100 ppm nitrogen.

SIZE AVAILABILITY

The typical weight of our diamond crystals is 0.2 – 3.0 carats which covers most industrial diamond applications.

Chemical and Physical Properties

The advanced HPHT process and thorough sorting ensure not only consistent high-quality grown diamonds but also repeatability in terms of chemical, physical, and thermal properties.

| Property | Value | Units |

| Hardness | 10,000 | kg/mm2 |

| Strength, tensile | >1.2 | GPa |

| Strength, compressive | >110 | GPa |

| Sound velocity | 18,000 | m/s |

| Density | 3.52 | g/cm3 |

| Young’s modulus | 1.22 | GPa |

| Thermal expansion coefficient | 0.0000011 | K |

| Thermal conductivity | 20 | W/cm-K |

| Thermal shock parameter | 30,000,000 | W/m |

| Debye temperature | 2,200 | K |

| Dielectric strength | 10,000,000 | V/cm |

| Electron mobility | 2,200 | cm2/V-s |

| Hole mobility | 1,600 | cm2/V-s |

| Electron saturated velocity | 27,000,000 | cm/s |

| Hole saturated velocity | 10,000,000 | cm/s |

| Bandgap | 5.45 | eV |

| Resistivity | 1013 – 1016 | Ohm-cm |

Mono Crystal Diamond Plates

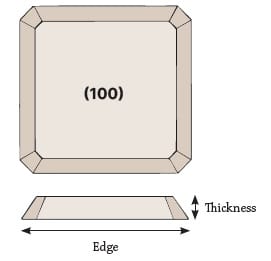

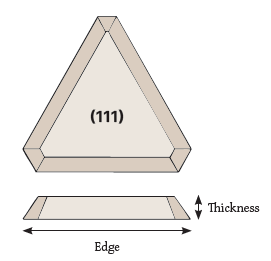

Synthetic Mono Crystal Diamond (MCD) Plates off er superior edge hardness and thermal conductivity, ideal for cutting tools, woodworking, wear parts, and surgical blades. Available in various crystal orientations, they help extend tool life and enhance performance.

PLATE SPECIFICATIONS

- Edge length ranges from 2 mm to 8 mm.

- Plate thickness can be customized based on your requirements.

- Available in various surface crystal orientations.

- Minimal deviation from the precise crystallographic four-point plane.

| Edge length | Thickness |

|---|---|

| 2.0 – 10.0 mm | 0.5 – 3.0 mm |

| Edge length | Thickness |

|---|---|

| 2.0 – 7.0 mm | 0.5 – 2.0 mm |

Mono Crystal Dresser

SPR’s MCD dresser bars are made from synthetic single crystal diamond, offering high thermal conductivity for heat dissipation and extended tool life. Precisely laser-cut from MCD (100) plates, these bars ensure uniform dimensions, durability, and reliable performance. Compatible with all dresser types and customizable in size, they are ideal for grinding applications requiring consistent and long-lasting results.

| Length | Width | Thickness |

|---|---|---|

| 2.0 – 6.0 mm | 0.5 – 2.5 mm | 0.5 – 2.5 mm |

APPLICATION OF MCD DRESSERS

The MCD Dresser Bar features a durable {110} plane working surface with high wear resistance and a precise laser-cut design. Its construction includes two {110} plane side faces and four {100} plane surfaces on the top and bottom, ensuring reliability and strength.