Mono Crystal Diamonds (MCD)

American Superabrasives Corp. The growth process of synthetic diamonds results in slight variations in each stone’s characteristics. Similar to mined diamonds, rough synthetic stones are meticulously sorted into different qualities and grades. Each grade takes into account factors like internal inclusions and irregular shape forms. Depending on the diamond’s intended application, specific grades are selected to minimize the chances of rejection during tool making.

Choose our lab-grown MCD for your production needs and enjoy the benefits of high-quality crystals throughout your entire manufacturing process.

Shape

ASC’ HPHT supply primarily consists of topped octahedron shapes in a standard controlled process. However, for larger sizes or specific crystal orientations, the shape may lean towards rhombi-dodecahedron or plate-like crystals.

Color

During the growth phase, diamond crystals acquire a subtle yellow hue, which does not compromise their performance. This coloration results from nitrogen atoms being trapped within the crystal’s lattice during synthesis. (synthetic crystal of Type Ib, containing approximately 100 ppm nitrogen).

Size Availability

The typical weight of our diamond crystals is 0.2 – 3.0 carats which covers most industrial diamond applications.

Oсtahedron topped perpendicular to the axis L4.

Chemical and Physical Properties

The advanced HPHT process and thorough sorting ensure not only consistent high-quality grown diamonds but also repeatability in terms of chemical, physical, and thermal properties.

| Property | Value | Units |

| Hardness | 10,000 | kg/mm2 |

| Strength, tensile | >1.2 | GPa |

| Strength, compressive | >110 | GPa |

| Sound velocity | 18,000 | m/s |

| Density | 3.52 | g/cm3 |

| Young’s modulus | 1.22 | GPa |

| Thermal expansion coefficient | 0.0000011 | K |

| Thermal conductivity | 20 | W/cm-K |

| Thermal shock parameter | 30,000,000 | W/m |

| Debye temperature | 2,200 | K |

| Dielectric strength | 10,000,000 | V/cm |

| Electron mobility | 2,200 | cm2/V-s |

| Hole mobility | 1,600 | cm2/V-s |

| Electron saturated velocity | 27,000,000 | cm/s |

| Hole saturated velocity | 10,000,000 | cm/s |

| Bandgap | 5.45 | eV |

| Resistivity | 1013 – 1016 | Ohm-cm |

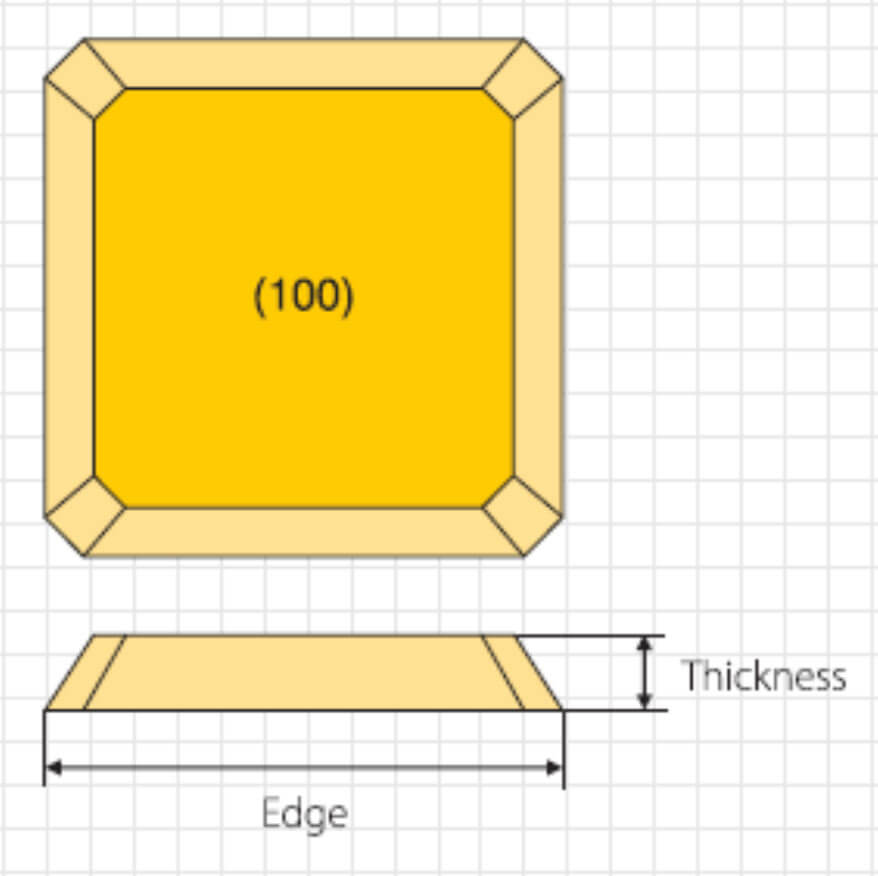

Mono Crystal Diamond Plates

The synthetic Mono Crystal Diamond (MCD) Plates open new advancements in tool-making. These plates offer exceptional edge hardness and high thermal conductivity, making them ideal for applications requiring long usable lengths or large planar faces/orientations. They are commonly used in creating cutting tools, woodworking tools, wear parts, and surgical blades. To support toolmakers in developing tools and wear parts with extended life, our company provides MCD plates in various crystal orientations.

MCD plate specifications

- Edge length ranges from 2 mm to 8 mm.

- Plate thickness can be customized based on your requirements.

- Available in various surface crystal orientations.

- Minimal deviation from the precise crystallographic four-point plane.

NAD’s (100) plate example

| Edge length | Thickness |

|---|---|

| 2.0 – 10.0 mm | 0.5 – 3.0 mm |

NAD’s (111) plate example

| Edge length | Thickness |

|---|---|

| 2.0 – 7.0 mm | 0.5 – 2.0 mm |

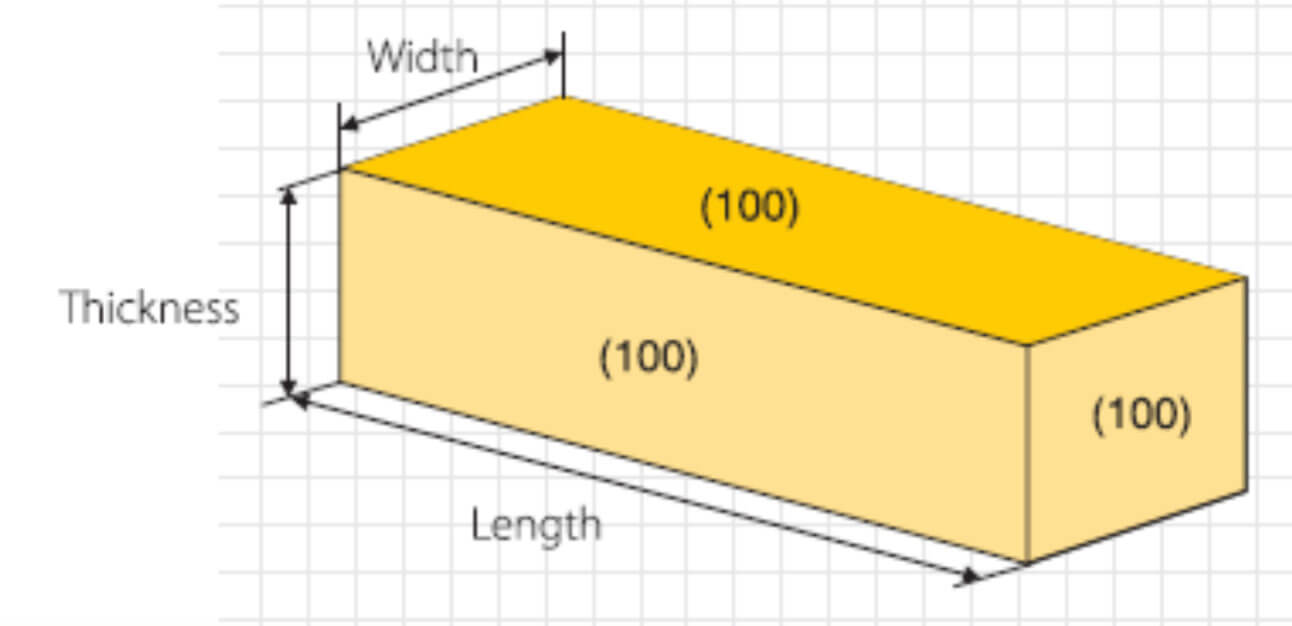

Mono Crystal Dresser

American Superabrasives provides MCD dresser bars, ideal for blade-type dressers used in grinding to ensure uniform dressing and a smooth surface finish. These dresser bars are made from synthetic single crystal diamond, known for its high thermal conductivity. This feature helps in dissipating heat from the grinding area, thus extending the tool’s life. The bars are characterized by their uniform dimensions, correct plane orientation, and consistent thermal management, making them a top choice for grinding dresser applications.

Available in various square and rectangular shapes and lengths, MCD dresser bars are precisely cut from MCD (100) plates using laser technology. These tools are highly stable, repeatable, and durable, offering longevity and consistent performance. They are compatible with all dresser types, including single point, multi-point, blade, and rotary dressers. Customizable in size to meet specific needs, MCD dresser bars are a reliable and high-quality solution for dressing requirements.

Application of MCD Dressers

The MCD Dresser Bar features a laser-cut end with a durable 2pt {110} plane working surface. Its construction includes two equally long 2pt {110} plane opposite side faces, and four equal length surfaces with 4pt {100} planes on the top and bottom. This ensures high wear resistance in the {100} direction of the 2pt {110} plane surface, which is perpendicular to the long 2pt {100} plane sides of the crystal.

| Length | Width | Thickness |

|---|---|---|

| 2.0 – 6.0 mm | 0.5 – 2.5 mm | 0.5 – 2.5 mm |