PCD

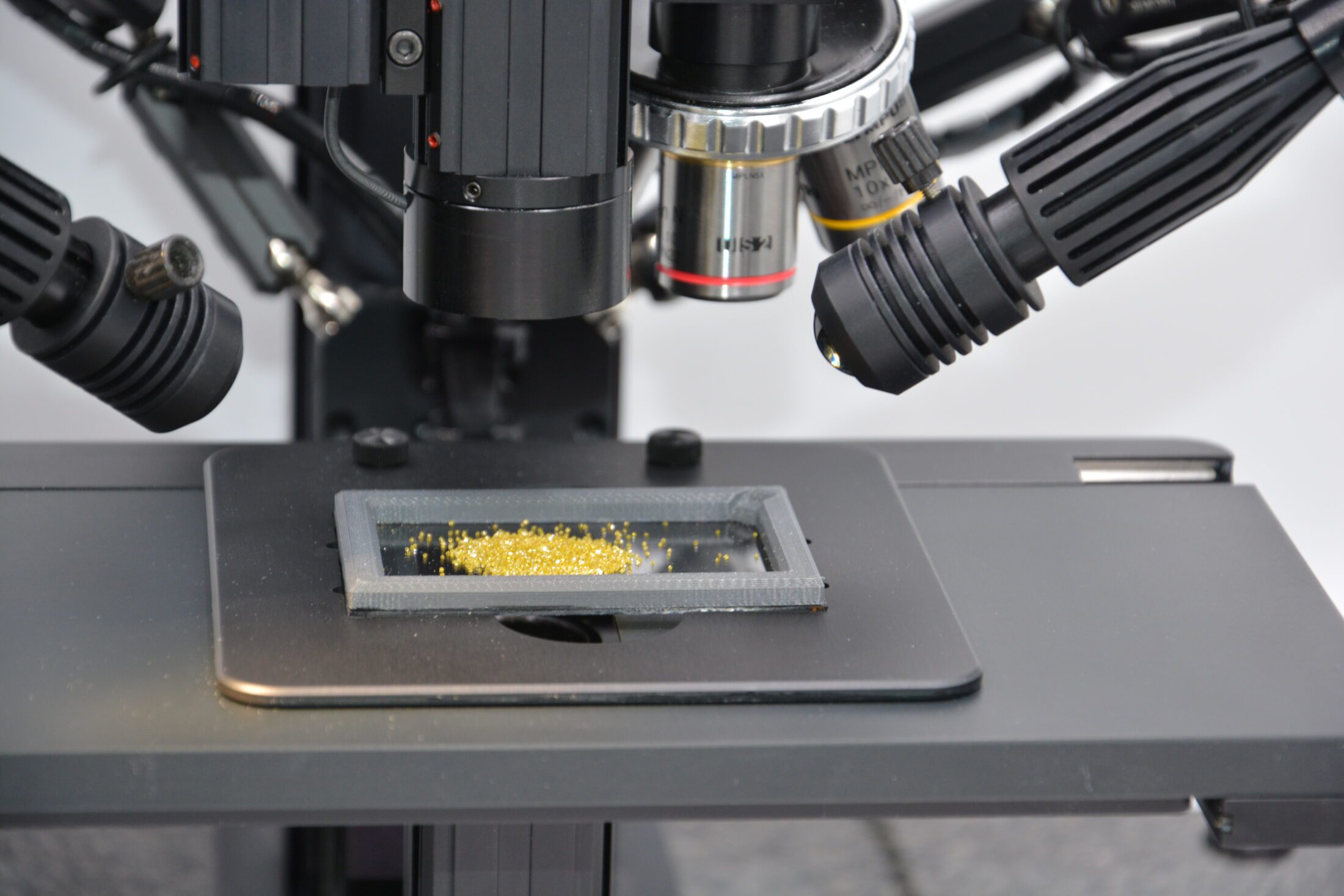

PCD, or polycrystalline diamond, offers unparalleled durability and performance. Our solids are a type of synthetic diamond product that is widely used in various industrial applications for cutting, grinding, and drilling operations. PCD is manufactured by sintering together micron-sized diamond particles under high pressure and temperature conditions, often with a metallic binder, which acts to cement the diamond particles together. This process results in a highly durable and wear-resistant material that exhibits many of the desirable properties of natural diamond, making it an excellent choice for tools that require superior hardness and longevity. As such, SPR Abrasives are setting new standards for cutting, grinding, and drilling operations.

In need of more information about our PCD?

The advanced quality of PCD

Our PCD not only has a superior quality, meticulously crafted using advanced technologies, but it has various incomparable advantages. As a solid, it has an exceptional hardness and wear resistance, an excellent thermal stability, a low coefficient of friction, and high material removal rates that improve productivity. Due to their durability and performance characteristics, PCD solids are used in a wide range of industrial applications. Some examples are:

- Machining aluminum engine components in the automotive industry: Ensuring high-precision machining at high speeds, cleaner cuts, and longer tool life.

- Drilling composite materials in the aerospace industry: Producing clean, precise holes in CFRP and GFRP with minimal delamination.

- Milling and cutting in the woodworking industry: Allowing smooth finishes and reduced downtime in high-volume production environments working with HDF, MDF, laminates and veneers.

- Manufacturing printed circuit boards in the electronics industry: Preventing damage to delicate components from heat generated during drilling and creating precise and high-wear resistant holes in the boards.

These applications underscore the versatility and value of our PCD solids in delivering performance and efficiency across diverse industrial sectors. The experienced team at SPR Abrasives has mastered the art of processing polycrystalline diamond and polycrystalline cubic boron nitride, ensuring that every product meets the highest standards of hardness and thermal stability. We offer a wide range of types and grades.

Looking for superabrasive powders?

Explore our specialized services

To discover the full potential of PCD in your industrial products, we invite you to contact SPR Abrasives. Our specialized services are tailored to meet the unique challenges and demands of our clients, offering customized solutions that leverage the exceptional properties of polycrystalline diamond, both in solid form as used as a base for synthetic diamond powder. We are able to provide any form you need. Our team is dedicated to helping clients select the optimal materials for their specific needs, ensuring the best possible performance and longevity. On top of that, as an innovative manufacturer of coatings, we encourage reusing and reclaiming existing materials in your industrial machinery. Engage with us to explore how our superabrasives can revolutionize your operations, delivering unmatched durability, efficiency, and value.

Curious about our products?